Your Trusted Industrial Valve Manufacturer

For over five decades, NSW Valve Manufacturer has been a global leader in precision valve manufacturing, delivering engineered solutions for the world’s most demanding industrial applications. As a specialist valve manufacturer, we combine cutting-edge technology with uncompromising craftsmanship to produce valves that ensure safety, efficiency, and reliability in your critical operations. Our extensive portfolio, including ball valves, gate valves, check valves, globe valves, butterfly valves, and ESDV valves, is designed to meet the rigorous standards of the oil and gas, chemical, power, and water industries.

Why Choose NSW Valve Manufacturer as Your Valve Partner?

Selecting the right manufacturer is paramount to your project’s success. Beyond mere supply, we offer a partnership grounded in expertise, quality, and unwavering support.

Over Five Decades of Manufacturing Excellence

Our long-standing history is a testament to our commitment to excellence and innovation. Since our founding, we have continuously evolved our processes and products, building an unparalleled depth of knowledge in fluid control dynamics. This experience translates into valves you can depend on for the long haul.

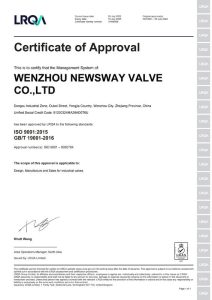

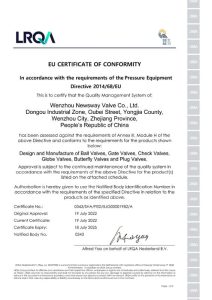

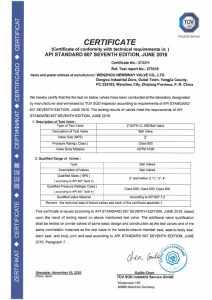

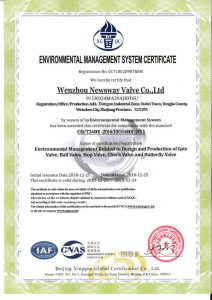

International Certifications & Quality Assurance (API 6D, API 6A, ISO 9001, CE, PED)

We operate within the framework of the world’s most stringent quality standards. Our certifications are not just badges on the wall; they are integral to our manufacturing DNA. Every valve undergoes rigorous testing and quality checks, ensuring full compliance and performance reliability for your specific application requirements.

Complete In-House Capabilities: From Casting and Machining to Testing

Unlike many competitors who outsource key production stages, we maintain complete vertical integration. Our state-of-the-art facilities house advanced foundries, CNC machining centers, and automated assembly lines. This end-to-end control allows for superior quality management, reduced lead times, and the flexibility to accommodate custom valve manufacturer requests.

Global Project Support & Localized Service

We serve a global clientele with a localized approach. Our network of experienced engineers and support staff provides timely technical assistance, on-site consultation, and after-sales service, ensuring you have a reliable partner no matter where your project is located.

Our Comprehensive Industrial Valve Product Portfolio

Explore our range of high-performance valves, each engineered for a specific purpose and environment.

Ball Valves

Key Features:

Bubble-tight sealing, low flow resistance, quick operation.

Our ball valves are designed for reliable shut-off with minimal torque. The precision-machined ball and seats ensure zero leakage, making them ideal for a wide range of fluids and gases.

Primary Applications: Oil & gas transmission, chemical processing.

They are the valve of choice for pipeline isolation, loading arms, and applications requiring frequent operation.

Gate Valves

Key Features:

Full-bore design, minimal pressure drop, ideal for isolation.

Our gate valves provide a unobstructed flow path when fully open, minimizing pressure loss. The rising stem design offers a clear visual indicator of the valve position.

Primary Applications: Water, steam, and oil pipeline isolation.

Perfect for mainline isolation duties in pipelines and plants where flow capacity is critical.

Check Valves

Key Features:

Prevent backflow, automatic operation.

Our check valves automatically prevent reverse flow, protecting pumps and compressors from damage. We offer swing, lift, and dual-plate designs to suit various flow conditions.

Primary Applications: Pump and compressor discharge systems.

Essential for any system where backflow could cause damage or process disruption.

Globe Valves

Key Features:

Precise flow throttling, excellent shut-off capability.

Designed for regulation, our globe valves offer superior throttling performance and dependable shut-off. The plug and seat arrangement allows for fine control of flow rate.

Primary Applications: Boiler feedwater, chemical process regulation.

Ideal for cooling water systems, fuel oil systems, and feedwater control applications.

Butterfly Valves

Key Features:

Compact design, lightweight, cost-effective.

Our butterfly valves provide an excellent combination of performance and value. The simple design offers a compact solution for on/off and modulating service with low maintenance needs.

Primary Applications: Water treatment, HVAC, power generation.

Widely used for handling large volumes of water, air, and other low-pressure fluids.

→ Explore Our Butterfly Valve Range

ESD Valves (Emergency Shutdown Valves)

Key Features:

Critical safety isolation, high reliability, fast response.

As a safety-critical manufacturer, our ESDV valves are engineered for rapid closure in emergency situations. They are designed to fail in a safe position and are often SIL-rated.

Primary Applications: Safety Instrumented Systems (SIS), oil & gas platforms.

Deployed in offshore platforms, pipeline block valve stations, and refinery process units to isolate sections and prevent incidents.

→ Explore Our ESDV Range

Industries We Serve

Our expertise as a valve manufacturer extends across key sectors where performance cannot be compromised.

Oil & Gas

Oil & Gas

From subsea wellheads to refining and distribution, our valves are built to handle corrosive, high-pressure, and critical safety applications.

Chemical & Petrochemical

Chemical & Petrochemical

We offer a range of alloys and designs resistant to highly corrosive and abrasive media, ensuring longevity and safety in complex processing plants.

Power Generation

Power Generation

We provide valves for critical high-pressure steam, feedwater, and cooling applications in nuclear, fossil fuel, and renewable energy plants.

Water & Wastewater

Water & Wastewater

Our valves ensure reliable and efficient flow control in potable water treatment, distribution networks, and sewage processing facilities.

Marine & Offshore

Marine & Offshore

Our products are designed to withstand the harsh, corrosive marine environment, meeting stringent international marine standards.

Our Core Values & Commitment

Quality First: An Uncompromising Principle

We never cut corners. Every decision is made through the lens of quality, ensuring the long-term reliability and safety of our products.

Driven by Innovation: R&D for Next-Gen Solutions

We invest heavily in research and development to pioneer new materials, designs, and smart valve technologies for the evolving needs of industry.

Sustainable Operations: Eco-Friendly Materials & Processes

Our commitment extends to the environment. We strive to minimize our ecological footprint through efficient manufacturing, waste reduction, and developing valves that enhance our clients’ operational efficiency.

Frequently Asked Questions (FAQ)

How do I select the right valve type for my application?

The correct valve depends on your service (isolation, throttling, prevention of backflow), the media (liquid, gas, corrosive, abrasive), pressure, temperature, and required safety integrity level. Our engineering team is ready to assist you with this critical selection.

What international standards do your valves comply with?

Our valves are designed and manufactured to comply with major international standards including API, ASME, ANSI, ISO, and EN. Specific certifications like API 6D, API 600, and ISO 9001 are core to our quality system.

Do you offer custom-engineered valve solutions?

Yes. Our in-house engineering capability allows us to design and manufacture valves to meet unique specifications, including special materials, dimensions, pressure ratings, and actuation packages.

What is your typical lead time?

Lead times vary based on the valve type, size, material, and customization requirements. While we stock some standard items, engineered solutions require manufacturing time. Contact us with your specific needs for an accurate timeline.

Contact Us for Expert Consultation

Ready to specify the optimal valve for your system? Have a technical question about an application? Our engineering and sales teams are here to provide expert guidance and support.

Contact us today for a consultation and a detailed quote. Let us demonstrate why we are the valve manufacturer of choice for industry leaders worldwide.

ISO 9001

ISO 9001 PED-CE

PED-CE API 607

API 607 ISO 14001

ISO 14001 ISO 45001

ISO 45001